Linear Low Density Polyethylene, commonly known as LLDPE, is a type of plastic that has gained significant popularity in various industries. This article will delve into the specifics of LLDPE plastic, its uses, and how it compares to LDPE (Low Density Polyethylene). We will also discuss its application in shrink bundling film.

What is Linear Low Density Polyethylene (LLDPE)?

LLDPE is a type of polyethylene, a common plastic material, that is known for its superior tensile strength and impact resistance. It is made by copolymerizing ethylene with longer-chain olefins. The ‘linear’ in its name refers to the absence of branches in its polymer chains, which results in a denser and more compact structure compared to LDPE.

Uses of LLDPE

LLDPE plastic is versatile and can be used in a variety of applications. Its high tensile strength and durability make it an excellent choice for products that require flexibility and resistance to punctures and tears. Some common uses of LLDPE include:

Packaging:

LLDPE is widely used in the packaging industry due to its strength and flexibility. It is used in the production of plastic bags, films, and containers.

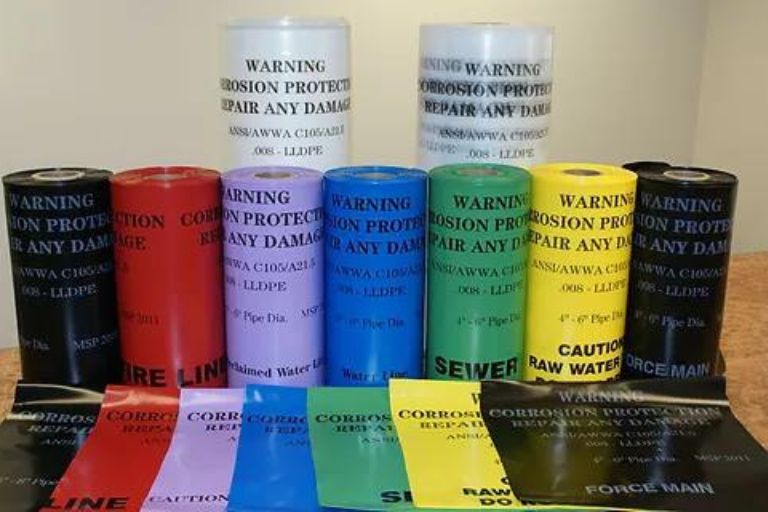

Pipes and Conduits:

LLDPE’s resistance to environmental stress cracking makes it suitable for pipes and conduits, especially those used for the transportation of gases and liquids.

LLDPE vs LDPE

While LLDPE and LDPE are both types of polyethylene, they have distinct differences. LLDPE’s linear structure gives it superior tensile strength and puncture resistance compared to LDPE. This makes LLDPE a better choice for applications that require durability and flexibility, such as shrink bundling film.

On the other hand, LDPE is easier to process and has better clarity, making it more suitable for applications where transparency is important.

Conclusion

In conclusion, Linear Low Density Polyethylene (LLDPE) is a versatile plastic material with a wide range of applications. Its superior tensile strength and puncture resistance make it an excellent choice for products that require durability and flexibility, such as shrink bundling film. While it shares similarities with LDPE, its unique properties make it stand out in various applications. Whether you’re in the packaging industry or looking for a durable plastic material, LLDPE is worth considering.

Get in touch with us

his is where we transform raw materials into the products you love. Our state-of-the-art facilities ensure the highest quality, and our dedicated team works tirelessly to exceed your expectations.

3 Industrial Park Johnstown, Colorado 80534

Send us a message

Question, need assistance, or want to share your feedback, we’re just a message away. Let’s start a conversation today!