The Ultimate Guide to Extending the Lifespan of Your Pipes with Polyethylene Encasement

Introduction

When it comes to safeguarding your underground pipes, one solution stands out for its reliability and cost-effectiveness: polyethylene encasement. Specifically, Linear Low-Density Polyethylene (LLDPE) wrap has proven to be a superior choice for prolonging the life of various types of pipes, including ductile iron and steel. In this comprehensive guide, we’ll explore the advantages of using LLDPE as your go-to ductile encasement wrap, and we’ll also delve into the different specifications set by the American Water Works Association (AWWA) for both printed and unprinted wraps.

Why Choose Polyethylene Encasement?

Polyethylene encasement serves as a protective barrier made from polyethylene resins. This barrier is wrapped around pipes to shield them from corrosive soil conditions, thereby extending their lifespan. Among the different types of polyethylene, LLDPE stands out for its flexibility, high tensile strength, and puncture resistance. These properties make it an excellent choice for pipe polywrap applications.

How LLDPE Extends the Life of Your Pipes

Resistance to Corrosion

One of the primary benefits of using LLDPE as your ductile pipe wrap is its ability to act as a physical barrier between the pipe and corrosive elements found in the soil. By preventing direct contact, LLDPE significantly reduces the rate of corrosion.

Acts as a Moisture Barrier

The impermeable nature of LLDPE makes it an effective moisture barrier. This is crucial for preventing rust and corrosion, further contributing to the longevity of your pipes

Withstands Chemical Exposure

LLDPE is chemically inert, offering resistance to a wide range of soil chemicals that could otherwise speed up the degradation of your pipes. This makes it an ideal choice for 8 mil encasement wrap applications where chemical resistance is a concern.

AWWA Specifications: Understanding the Difference Between Printed and Unprinted Wraps

When it comes to polyethylene encasement, the American Water Works Association (AWWA) has set forth guidelines to ensure quality and performance. Among these, AWWA C105 is the most commonly cited standard for polyethylene encasement designed for ductile iron piping. This standard outlines the material, performance, and installation requirements for polyethylene encasement and is considered the industry benchmark.

AWWA C105: The Gold Standard

AWWA C105 is specific to polyethylene encasements used for the protection of ductile iron pipes and fittings. It outlines the minimum requirements for materials, including the type and grade of polyethylene to be used. The standard also specifies installation procedures to ensure that the encasement serves its purpose effectively. When you see a polyethylene encasement wrap labeled with AWWA C105, you can be assured of its quality and suitability for ductile iron pipe protection.

Printed vs. Unprinted Wraps

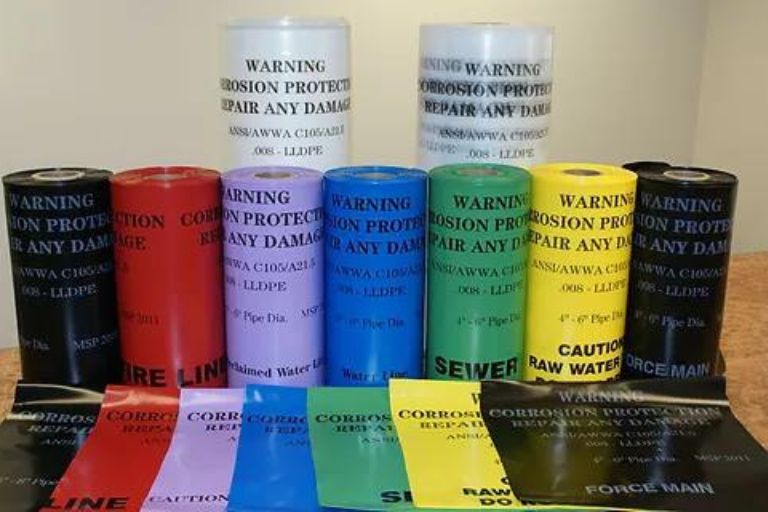

Printed Wraps:

These usually come with important information printed directly on the wrap. This can include the manufacturer’s name, the pipe size it’s designed for, and a statement indicating compliance with AWWA C105 or other relevant standards. Printed wraps offer the advantage of easy identification and assurance of quality, as they clearly indicate compliance with industry standards.

Unprinted Wraps:

These are plain polyethylene encasements that offer the same level of protection as their printed counterparts but lack the printed information. While they may still meet AWWA C105 standards, you’ll need to refer to the product documentation for that assurance.

Other Specifications

While AWWA C105 is the most commonly recognized standard, there are other specifications that polyethylene encasements might meet. These could be industry-specific or related to other types of pipes like steel or PVC. Always check the product documentation to ensure that the wrap you’re considering is appropriate for your specific application.

Conclusion

Choosing the right polyethylene encasement wrap is crucial for extending the life of your pipes. Understanding the differences between printed and unprinted wraps, as well as the importance of AWWA C105, can help you make an informed decision. Whether you’re in the market for 8 mil encasement wrap or exploring other thickness options, knowing what to look for will save you time and money in the long run.

Get in touch with us

his is where we transform raw materials into the products you love. Our state-of-the-art facilities ensure the highest quality, and our dedicated team works tirelessly to exceed your expectations.

3 Industrial Park Johnstown, Colorado 80534

Send us a message

Question, need assistance, or want to share your feedback, we’re just a message away. Let’s start a conversation today!